How To Build A Window Well Out Of Wood

If you need to replace your window well covers you'll quickly notice that the off the shelf options can be expensive! In this article, I'll be covering how to build your own set of DIY window well covers from wood for a fraction of the cost.

Whatever successful DIY project requires a fleck of planning, and then here's a quick listing of the tools that you'll find useful for this project.

Tools & Supplies Needed

Tools:

- Drill or impact driver

- Tap measurer

- Saw

- Sawhorses (optional but handy!)

Supplies:

- 1″ 10 four″ pressure treated board

- 2″ x 4″ pressure level treated board

- 2″ outdoor wood screws

Tip: I'll show y'all how to notice out exactly how many boards are needed once you've had a run a risk to measure your window well(s).

Steps for DIY Window Well Covers

Step 1: Mensurate your Window Wells

In order to know exactly how many boards will be needed for the projection, you'll demand to go out and measure the size of your window wells. Brand sure to mensurate each and every window well that will need a new embrace equally it's common for a home to accept more than than ane size.

At that place may also be variations between each that require slight differences in the assembly, so make a few measurements, jot them down somewhere handy, and get ready to cut!

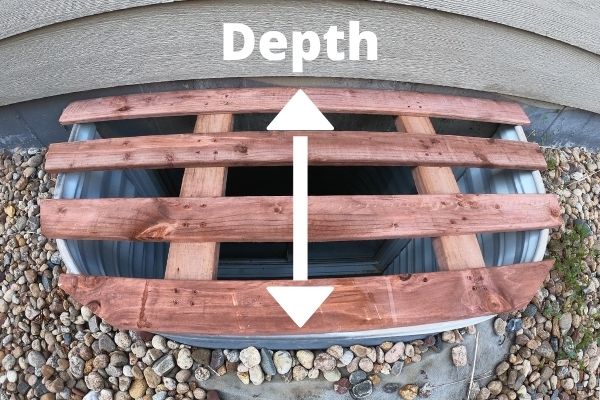

You will need to find the widest part of the well (likely adjacent to the house) and it's maximum depth (firm to forepart lip).

Tip: For the depth measurement, brand sure to measure to the inside edge of the window well encompass to ensure that the vertical runners volition just fit inside of the well.

Now – make sure that you write downward these measurements somewhere safe so that you don't lose them and need to remeasure!

Repeat these measurement steps for each window well. Measuring to the nearest 1/eight inch is precise enough for this projection.

Step ii: Summate Materials Needed

Once you have all of your measurement, you'll need to practise some quick math to ensure that yous purchase enough raw materials i.eastward. wood.

I'll walk through how to make this simple calculation with my window well sizes, simply y'all'll demand to apply the aforementioned approach to your own since they are probable different in size!

I used 2×4-inch boards for my vertical runners, and 1×4-inch boards for the horizontal ones, simply if you lot'd prefer to employ something stronger like all 2×4's then that certainly will piece of work as well.

Each window well cover has two vertical runners, then you'll want to multiply the depth past two for each window well and add together them up. In my case, I had iii window wells that were 24 inches deep, and 1 that was 36 inches deep.

Ex. (24 inches * two * 3) + (36 inches * 2) = 216 full inches

Now that you've got the full corporeality of forest, you'll want to add 10% for overage, mistakes, etc… to bring the total in my case to 238 inches. Now carve up that total past the length of boards that you'll be using.

8-foot lengths (72 inches) are the about mutual, but but double check here.

Ex. 238 / 72 = 3.3

Round up to the nearest whole board since you typically tin't buy partial lengths i.e. 4 in this example. In my setup, this is how many treated ii×4's I then purchased for the project.

Next upward, information technology's time to figure out how many one×4's that you will need!

For this step, you lot can choose to add more than or less boards, but for safe, I chose to have a board roughly every half-dozen inches.

For a 24-inch depth, that meant that iii of my window wells would take 4 horizontal boards, and I used 5 on my larger (36-inch well).

To summate the linear feet needed for each window well:

- Add iv inches to the width measurement for each well (to allow for overhang)

- Multiply by the number of boards on that well

- Repeat steps ane-2 for each well and add together together to go a total linear feet

- Divide the total linear feet past the lath length (likely viii feet again)

- Circular up to the nearest whole board

Take a deep sigh of relief now that the math is complete!

With the math out of the fashion, head to your local hardware or lumber supply store to buy the necessary number of 1×4's and two×4's. Brand sure to use pressure treated lumber every bit it will be exposed to the air current, rain, snow, etc…

Tip: If you're worried about messing up the math, go ahead and purchase a couple extra of each equally you tin can always render them later!

Stride 3: Cut Your Boards

Using your previous measurements, get alee and cutting down all of the 1×iv's and ii×4'due south down to their respective measurements.

The cuts for the 1×4's don't need to exist perfect, just reasonably shut in length every bit you lot will be trimming many of them afterward on.

You will want to endeavour and become the 2×iv'southward very close to their measurements as y'all want them to have a snug fit in the window well. Because of the curve in the window well, I'd recommend cutting the ii×4's about ii inches shorter than your actual measured width to ensure that they're able to slide down within the well.

A round or table saw will make this much easier, but you tin can always consummate this step with a hand saw if needed likewise.

Step 3: Assemble The Window Well Frame

Lay 2 2×4'south on the footing parallel to each other that are spaced out past one-half the width of the window well. Lay one 1×4 across one terminate, and a 2nd 1×4 across the other end.

Allow each 1×4 to hang 1 inch off the stop of the ii×iv and so that it can act equally a take hold of.

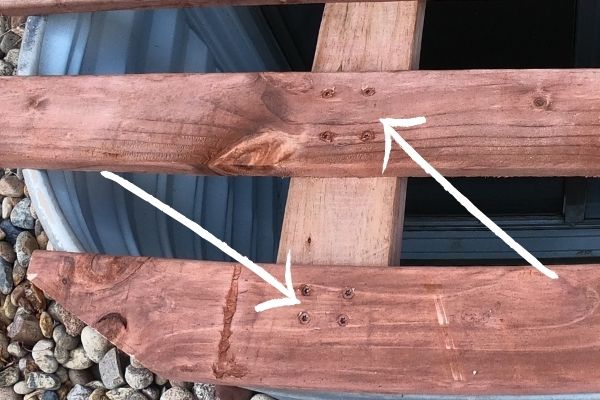

Use a single screw to attach the 1×4 and 2×4 at each spot where they cantankerous (4 total).

Take the frame to the well and do a quick exam fit to ensure that information technology's able to fit down in the well. If the 2×4'southward are too long to permit the frame to sit down inside, so they are too long and will demand to be trimmed shorter.

This is besides a good chance to ensure that the ends of the one×four's become past the edge of the window well and leave an overhang. Likewise much overhang is ok as these ends tin can be trimmed down after.

However, not fully going past the window well edge is bad because it won't be strong.

If demand be, unscrew and re-spiral the boards to make everything line up correctly and only movement on once information technology all lines upwards!

Step 4: Add The Remaining Boards

In one case y'all've confirmed that the window well cover properly fits, add remaining screws to the existing stop boards to lock them into identify. I used 4 screws on each board for extra security.

Afterwards securing the end boards, add the middle boards and secure them in identify with several (three-4) screws at each crossing indicate.

The middle boards should be evenly spaced out to foreclose there from being any overly large gaps in the embrace.

Footstep v: Trim The Lath Ends (optional)

At this bespeak, you should accept a fully functional window well cover that'due south ready to serve its purpose!

However, if you desire to tidy things up a lilliputian by trimming the excess edges off that volition make them look a little nicer.

I used a straight edge to mark a line in pencil that left at to the lowest degree a 1 inch overhang past the well edge, and so used my saw to trim information technology off.

Repeat this process for whatsoever remaining window well covers and yous can phone call this project done!

Decision on DIY Window Well Covers

It's worth pointing out that these window well covers are meant to prevent deadly accidents, not be used for common action. Children, pets, and adults should avert playing on or around them.

Because these window well covers are made from wood, you'll as well observe that they will need to be replaced over fourth dimension. While treated woods slows the rotting process, somewhen the lord's day and moisture will weaken the wood to the betoken that information technology's no longer safe and volition need to be replaced.

These window well covers cost around $25 each to make and ii hours of time. Which felt like a steal compared to the overpriced flimsy plastic ones found in well-nigh hardware stores!

Related Manufactures

If you found this article helpful, then brand certain to besides have a await at some of these related posts before you get!

- How To Reupholster Bar Stool Seats

- Ways To Upgrade Your Kitchen Cabinets (Without Painting Them)

- Will Home Depot Cutting Forest For Yous?

How To Build A Window Well Out Of Wood,

Source: https://projectperfecthome.com/diy-window-well-covers/

Posted by: labombardtrage1936.blogspot.com

0 Response to "How To Build A Window Well Out Of Wood"

Post a Comment